ROLLING PROCESS

Process control

Process simulation & optimization

Rolls

- Sleeved rolls

- Optimal grinding of rolls

- Optimization of BuR grinding & performance

- CoolRoll software

- Section cooling

Know-how

- Technological audits

Technological audits

Audit of technology is an analysis of existing technological conditions of rolling, making computer simulations, parametric studies or process measurements resulting in proposals of technological measures to achieve the desired target of rolling or cooling.

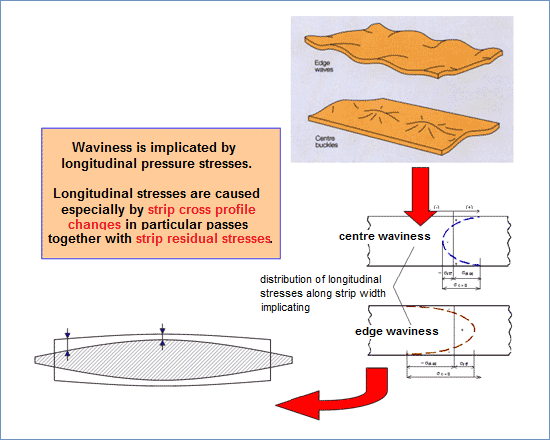

Technological audit of the profile and flatness of strips and plates

The target of the technological audit of the profile and flatness of strips and plates is reaching the desired profile or suppressing unwanted waviness of hot or cold rolled flat production.

The audit of technology is based on actuators that are on the rolling mill available. Generally we can take into account effects of the following actuators:

- optimization of bending forces,

- modification of grinding of rolls,

- axial shifting of rolls,

- section cooling of work rolls,

- modification of pass schedule.

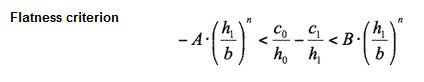

Bending forces optimal sequence specification represents the determination of such a crown progression in particular passes which would cause minimum strip longitudinal stress (not get over the flatness criteria).

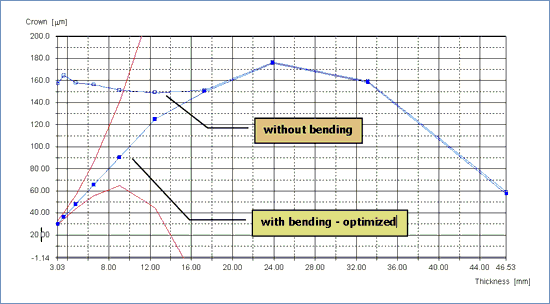

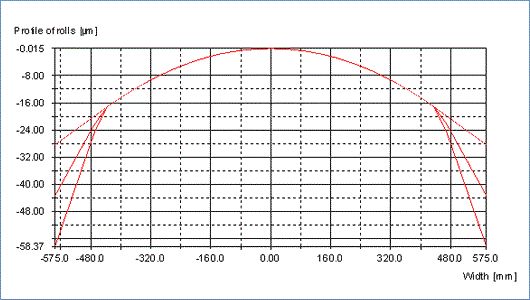

Through the work and backup rolls proper grinding the strip flatness can be achieved as well as bending forces extending in the allowed range during the whole work rolls campaign. While rolling a strip with a stable width (a situation usual at cold mills), through a special grinding it can be achieved still better flatness than on usual rolls with a parabolic profile.

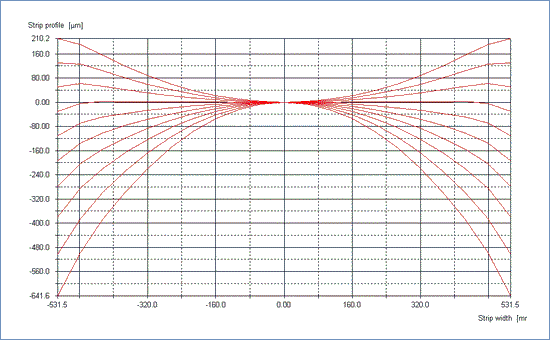

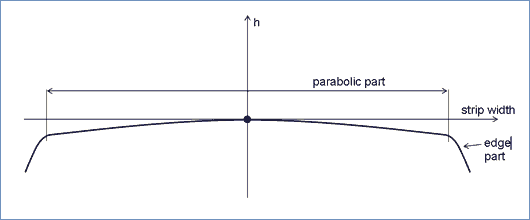

Typical cold strip profile with an abrupt thickness reduction on its edges is presented on the following picture. This phenomenon implicates often occurence of edge waviness.

This feature can be prevented with a help of a special grinding shape – see the following figure:

References:

The analysis of problems with profile and flatness on the HSM (Saldanha Steel, South Africa)

Modifications of models for flatness on Twin Steckel in control system (LIBERTY Ostrava, Czech Republic)